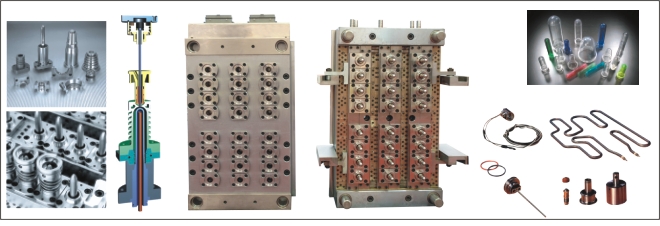

Горячеканальный систем для PET пресс-форм

PET Preform Moulds

Preform molds are produced at dedicated facilities in China. Preform molds range up to 96 cavities and offer:

Productivity

- Fast cycling due to specially designed cooling circuits

- Part ejection sensors that monitor preform transfer to the take-off plate, improving cycle time

- Standard interchangeable mold components; replacement parts available within 72 hours

Reliability

- Rugged design for long life

- Auxiliary tapers that reduce mold wear by pre-aligning the mold halves prior to the engagement of the neck ring tapers

- Roller cams that actuate both the opening and closing actions on the thread splits

Part Quality

- Lowest cavity-to-cavity weight and dimensional variation as a result of best-in-class manufacturing machines and processes

- Water hoses that are manifolded at the bottom of the mold, eliminating potential for water marks on preforms